Slide

Turbidity Analysis Simplified

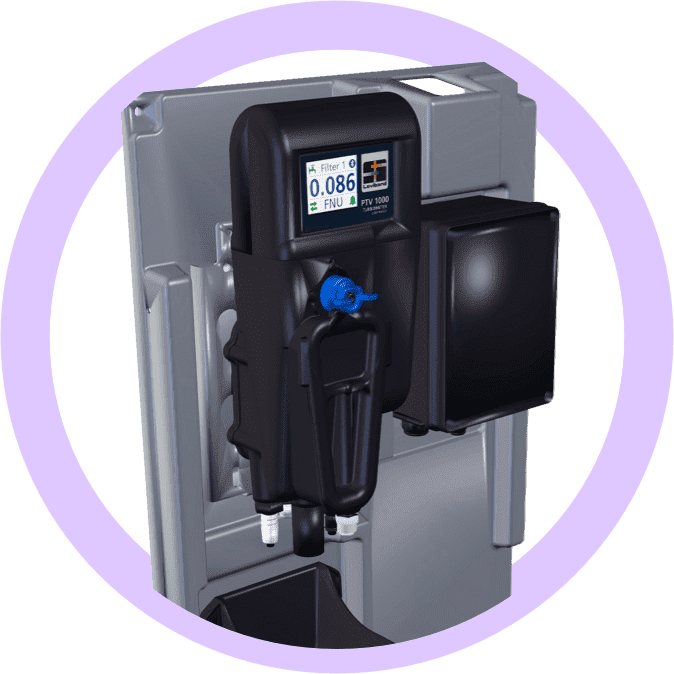

The PTV 1000 is our all-new turbidity analyser for low-level turbidity measurement in drinking water and other applications.

Slide

The PTV 1000 is our all-new turbidity analyser for low-level turbidity measurement in drinking water and other applications.

| Feature | Advantage | Benefit |

| Small volume flow body | Reduced water consumption Faster response times Easier to clean | Reduced water loss Reduced calibration solution requirement Early notification of an event Lower maintenance |

| Internal ‘light dump’ | Captures stray light – increased reproducibility | Improved performance |

| Innovative design | Removes bubble interference Easier to clean No ‘nooks and crannies’ Compact size Easy access for grab samples Icon based interface | Lower maintenance Improved performance Easy operation |

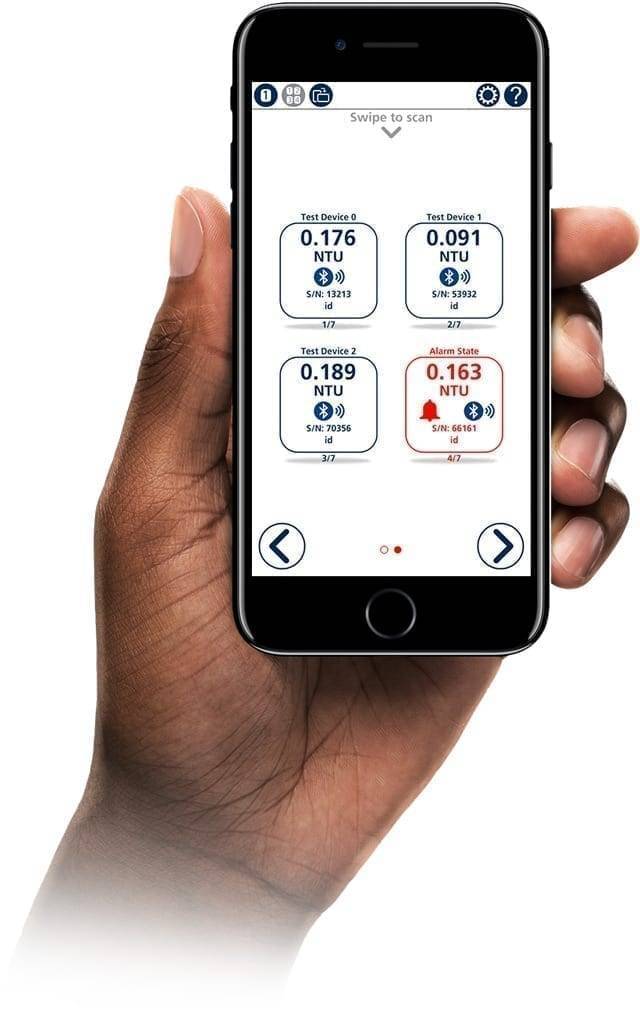

| Mobile interface | Control/manage multiple instruments with one controller Data and statistics manager | All info is in one location |

| Wet standard calibration | Calibration with primary standard made easy and safe | Absolute confidence with no risk to user |

We have added some short video tutorials which are designed to give you a brief introduction to installation, calibration, verification and maintenance of the PTV 1000 turbidity analyser.

The T-CALplus™ packaging is highly durable, which results in the user never coming into contact with the solution. Exposure to chemicals is immediately eliminated.

For mixing start by squeezing and manipulating the packaging for around a minute to ensure it is accurately mixed, and it’s ready to use.

Having Bubbles in your sample can be a significant interference in turbidity measurement. Our T-CALplus™ packaging is vacuum sealed, allowing users to mix a bubble free standard.

Discover how the use of T-CALplus™ Standards simplify the calibration and verification process.

If you’re happy using secondary solid standards for verification, no problem, they’re available too.

By incorporating procedures and technical pointers, all users have quick and easy access to everything they need at their fingertips.

For security purposes, we employ the latest proximity sensors to allow the operator to work on the sensor. Combining this with the ability to password protect two layers of access, operators and supervisors can be assured of data integrity.

Operators can extract vital data which can help identify trends faster by viewing or exporting the information for a selected period as a table or as a graph.

App based interface means operators find it easy to use and navigate. No more complicated menu structures!

With over 25 years of experience designing some of the worlds most popular turbidity instruments, Mike Sadar is well known as a turbidity expert across the globe. At WWEM 2018, Mike joined PMA to present the new PTV1000 turbidity analyser and we took the opportunity to interview him about his career and how to design the best turbidity instrument possible.

Want to know more about how to install and use your PTV1000?

Check out these handy video guides to ensuring you get the best from your turbidity analyser.

Flow accelerated corrosion has been demonstrated as one of the leading causes of corrosion in heat recovery steam generators. However, monitoring of the total iron in the boiler feedwater can be challenging with a lean operation given the low levels of total iron that are to be expected when flow accelerated corrosion is under control.

Turbidity can be a complex measurement to do, especially at the very low levels required in UK drinking water production. Measurement can be affected by the size and shape of the material scattering the light, the sample colour and then the distribution of the material in the sample.

“We have installed 3 demonstration units and each installation was a breeze that delivered excellent data. You can immediately tell it is a better measurement than the older technology by the lower reading it provides. The patented light dump does an excellent job of eliminating stray light.”

We greatly value all of the inquiries which our products and services generate and we are very confident that we will have the right solution available for you at the first point of contact when you reach our experienced team of engineers.

Contact us directly

at [email protected]

Established in 1971 PMA is a well-recognised provider of online instrumentation for process control and compliance monitoring. With expertise in analytical techniques such as Photometry, Colorimetry, Ion-selective electrodes (ISEs), Titration, Fluorescence, Ultrasonics and more.

Customer satisfaction rating in compliance with ISO/TS 1004:2012: Quality Management System Guidelines